The images are examples. For detailed information, other images and documents, please select individual articles from the following table.

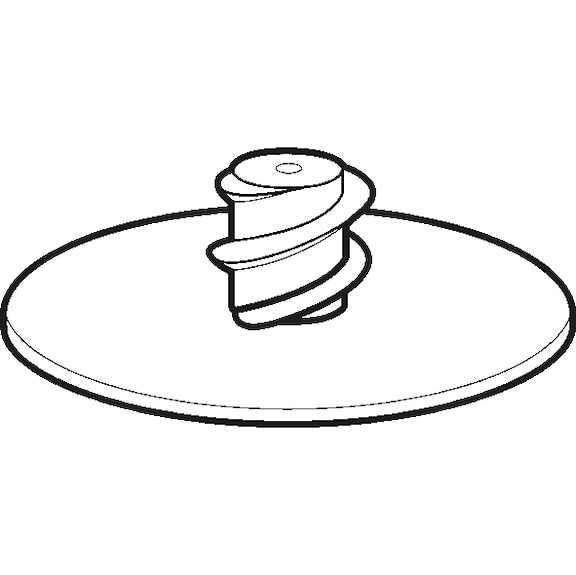

Lamella flap disc Mini-Disc alumina zirconia

Compatible with 3M Roloc system

Register now and access more than 15,000 products

Variants

Register now and access more than 15,000 products

Call customer service: +353 61 430200

Prices for customers after login

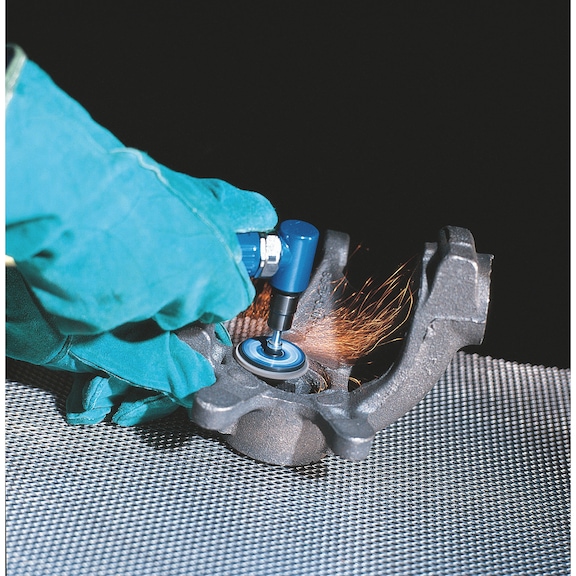

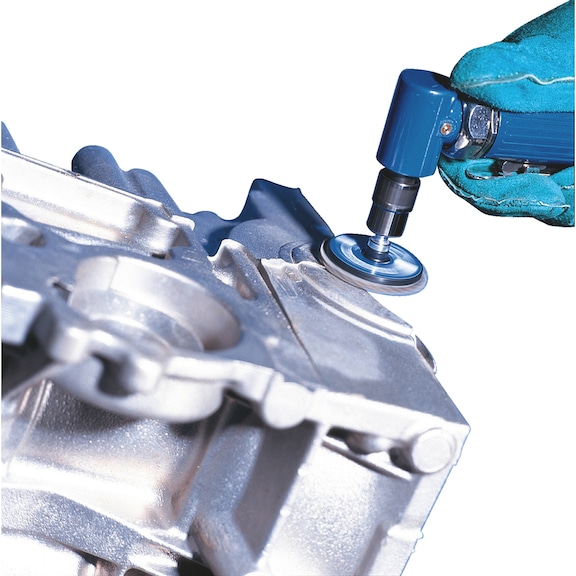

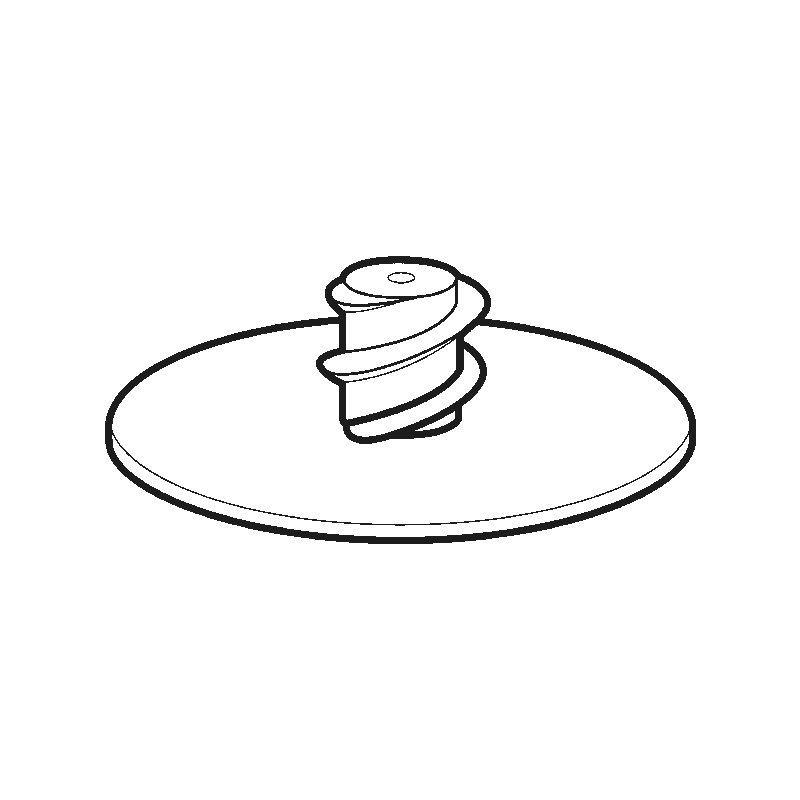

Mini segmented grinding disc with quick-change mounting for use on pneumatic axial grinders (angled), flexible shafts.

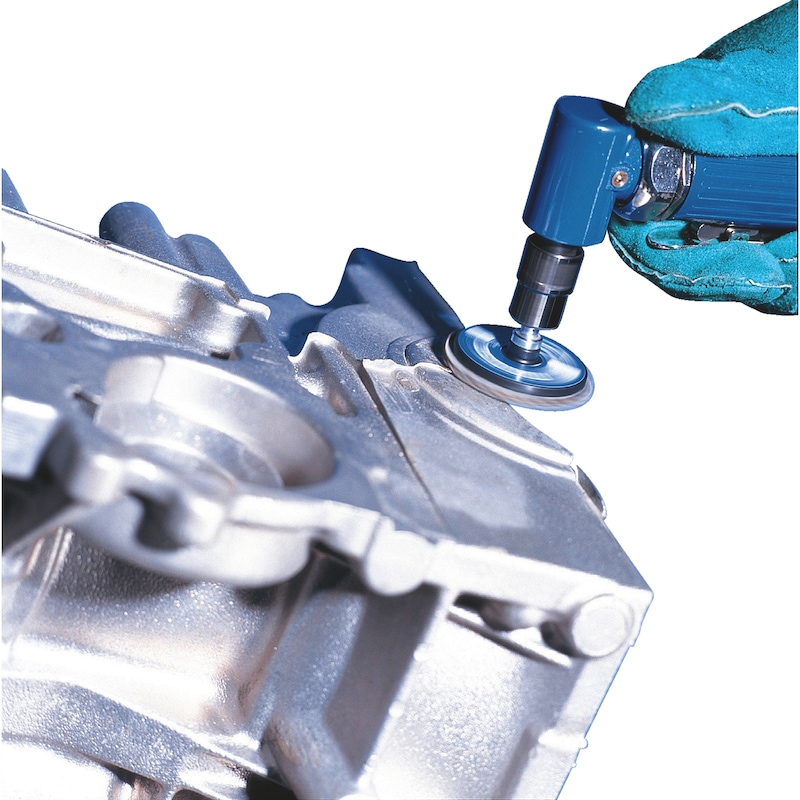

76-mm ∅discs can also be used on 115-mm pneumatic or electric angle grinders in conjunction with M14 holder

Sturdy plastic disc with rapid-change mount

Robust and flexible cotton fabric with a high level of tear resistance

Service life comparison: Conventional fibre disc: Mini-disc = 20: 1

Additional advantages of the mini-disc over comparable fibre discs:

- Up to 20x (15x) longer service life of mini-discs, especially when sanding edges

- All other advantages of segmented grinding discs compared with fibre discs

- No clogging or lubrication

- Versatile, broad range of applications

- Considerably finer surfaces possible with same grain

- Higher tear resistance when sanding corners and edges

- Increased removal rates

- Shorter machining times

- Considerable time and cost savings for the user

Alternative to quick-change system fibre wheels, small rough grinding discs, sanding tips, flap wheels, abrasive sleeves, abrasive caps etc.

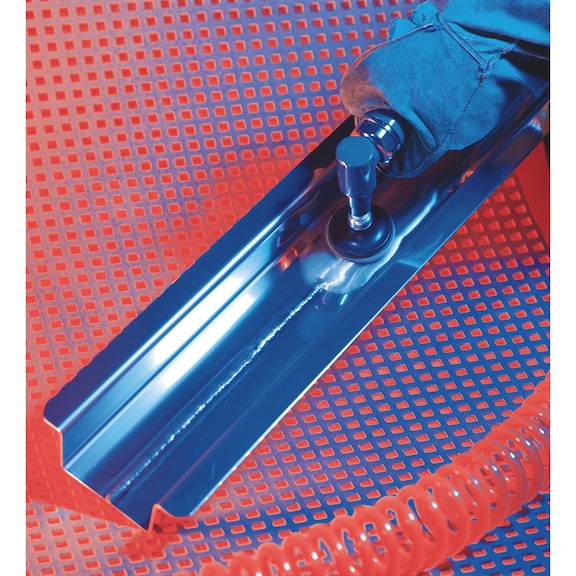

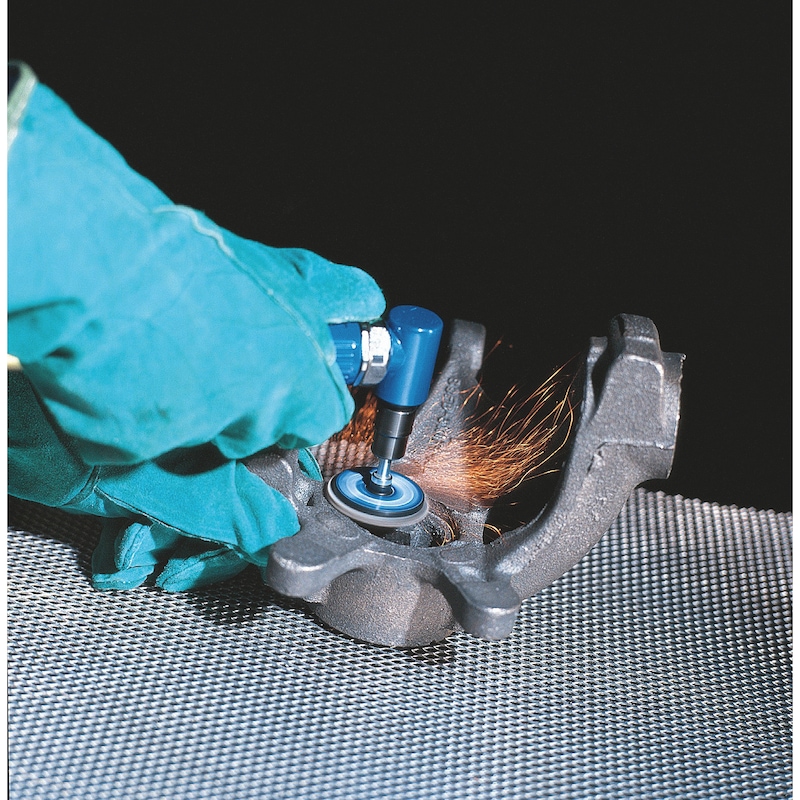

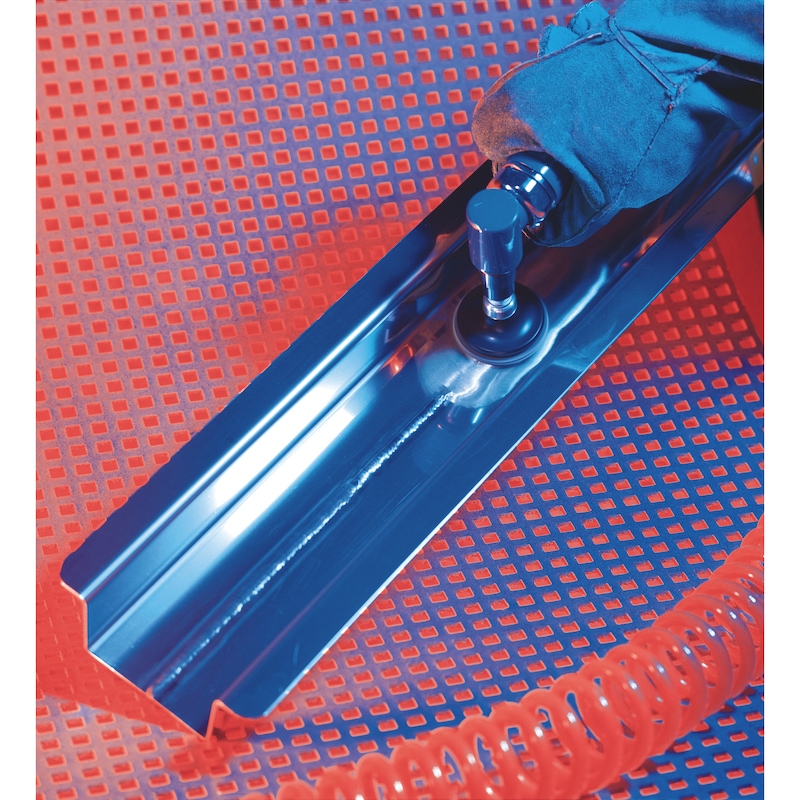

For machining welding seams, sanding surfaces, removing lacquer and paint, sharpening tools, dressing and smoothing, deburring, edge and finish machining, derusting, especially in hard-to-reach places.

Materials to be processed: Especially for stainless steels, chrome and nickel alloys. Alloyed and non-alloyed steel, construction steel, tool steel, non-ferrous metals, cast metal, hard plastics and wood.

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!