Perfect copper spray

Metal surface-Copper spray perfect

PNTSPR-CU-PLUS-400ML

Register now and access more than 15,000 products

High coat thickness with the first spray pass

- Very safe due to optimal protection against the elements

- Minimal time required, as only one work step is necessary

- Provides good coverage

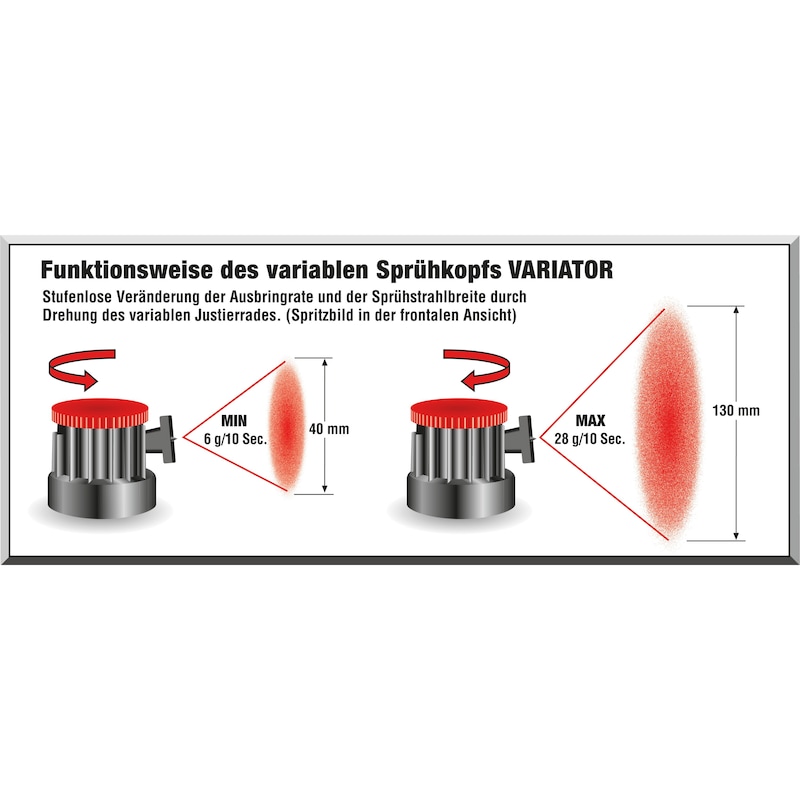

Versatile use thanks to adjustable spray head

Large-area and minor repairs can be carried out quickly and safely with the adjustable spray head.

High degree of resistance to running

High abrasion resistance

This information corresponds to the current state of our knowledge and is intended to provide information about our products and their possible applications. This information therefore should not be interpreted as a guarantee of certain properties of products or their suitability for a specific application. Warnings on the product labels must be observed. Not suitable as a primer for PU, MS polymer or hybrid sealing compounds.

The usage instructions are recommendations based on the tests we have conducted and are based on our experience; carry out your own tests before each application. We do not assume any liability for a specific application result due to the large number of applications and storage and processing conditions. Insofar as our free customer service provides technical information or acts as an advisory service, no responsibility is assumed by this service except where the advice or information given falls within the scope of our specified, contractually agreed service or the advisor was acting deliberately. We guarantee consistent quality of our products. We reserve the right to make technical changes and carry out further development.

Datasheets(X)

Satin-gloss copper spray for indoor and outdoor use with very good application, high coverage and excellent surface appearance. For universal use. Spray jet width adjustable thanks to an adjustable spray head. For visual enhancement, repair and protection against corrosion of metallic surfaces.

The base material must be clean, dry and free from grease. Remove rust and old loose paint, sand and clean. Vigorously shake the can for approx. two minutes before use.

Chemical basis | Nitrite combination resin |

Contents | 400 ml |

Colour | Copper coloured |

Fully hardening/curing conditions | At recommended dry layer thickness |

Curing time | 90 min |

Dust-drying time | 6 min |

Conditions for dust-drying time | at recommended dry layer thickness |

Dry layer thickness (first back-and-forth motion) | 36 µm |

Recoatable/Can be painted over | Conditional, preliminary testing required |

Density | 0.75 g/cm³ |

Density conditions | at 20°C |

Max. temperature resistance | 100 °C |

Shelf life from production | 24 Month |

Conditions to maintain shelf life from production | at 10°C to 25°C |

Grip strength | 17 min |

Grip strength conditions | at recommended dry layer thickness |

Cross-cut test | MAN 0-1 |

Cross-cut test conditions | in accordance with DIN 53151 |

Spot weldable | No |

Substrates with good adhesion | Copper |